Lonyan Eteng Eletronics Co.,Ltd Conductive adhesive tape,EMI Gasket,Thermal Pad |

(ET600) IC Graphite Thermal pad

Description

Thermal Flexible Graphite pad is a new heat-conducting and heat dissipating material. It conducts heat evenly along both sides,shielding the heat source from the components while improving the performance of consumer electronics.

The color is usually black, and the material is natural graphite, which has been refined. The thermal conductivity is up to 1500W/m-k in the horizontal direction

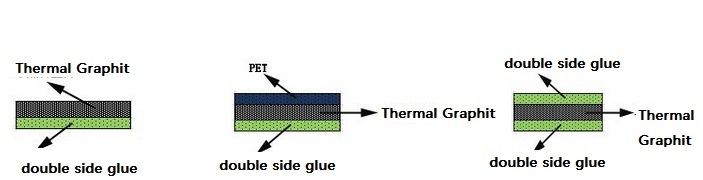

Structure

Synthetical Pyrolytic Graphite sheet feature:

1.High heat transfer efficiency: |

|

2.Easy processing: |

A flexible diaphragm,easy cutting and processing into any shape and can be repeated bending |

|

|

|

|

The horizontal and vertical direction can evenly heat conduction

1.Low thermal resistance, thermal resistance than aluminum - low 40%, 20% lower than the copper

2. weight - the weight lighter than aluminum 25%, lighter than copper 75%

3. The high thermal conductivity, coefficient of thermal conductivity - best for aluminum, copper 4 ~ 5 times

4. soft, easy operation - graphite pad can smooth the attached to the plane and curved surface, and can according to the customer demand to cut into any standard

Key property:

1.Ultra-high thermal transfer performance / easy to operate

2.Low thermal resistance

3.Light weight

Typical application:

-between the Circuit board chip and heat sink of LCD-TV

-PDP chip and IC

-between the transformer and the shell.

-between Led particle base and aluminum plate

-between PCB board and its shell

-between IC and heat sink

-laptop NB display card and network card

-between STB C and heat sink or shell

If you need other Thermal conductivity pad W/m.K,please see below link

(ET100) 1.0w/m-k

(ET150) 1.5w/m-k

(ET200) 2.0w/m-k

(ET250) 2.5w/m-k

(ET300) 3.0w/m-k

(ET350) 3.5w/m-k

(ET400) 4.0w/m-k

(ET500) 5.0w/m-k

(ET600) IC Graphite Thermal pad